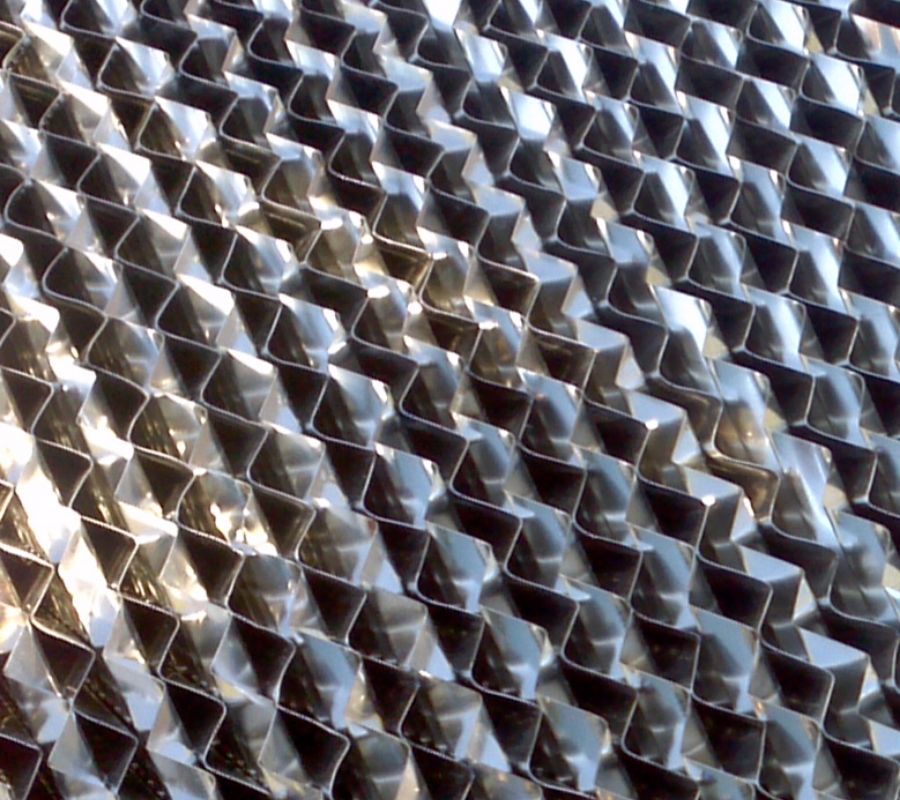

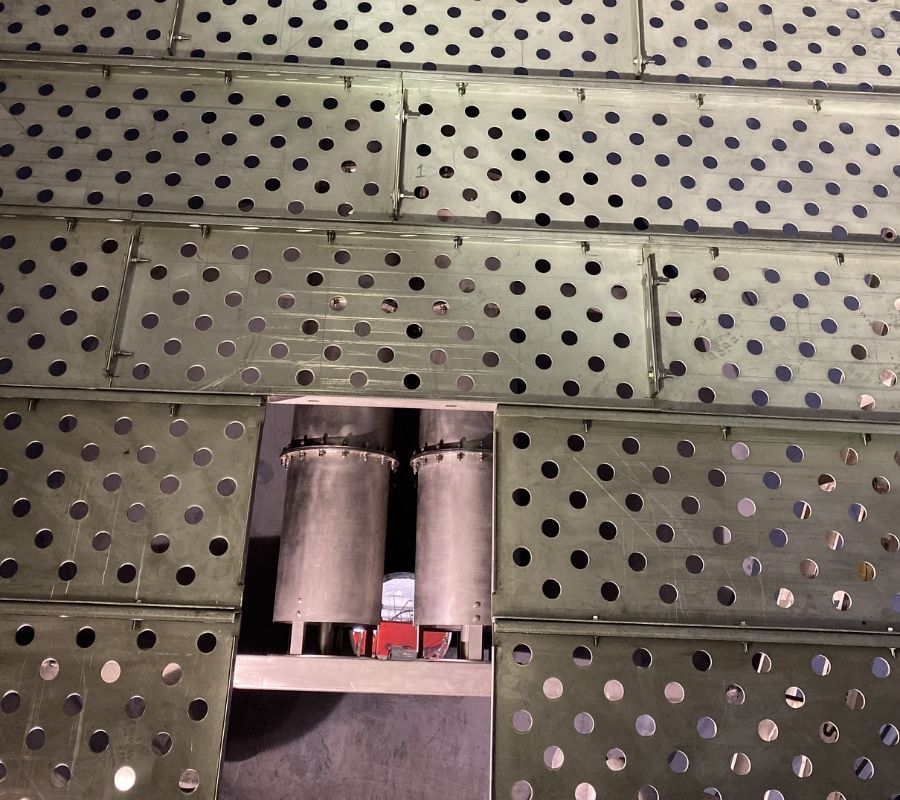

Perforated baffles using circular holes are traditionally used for most applications due to their good performance and general robustness. For more difficult services (heavy, viscous, or fouling applications) we would recommend a vertical slotted baffle style that creates less drag and is less prone to silt build-up. Mechanical foam breakers (defoamers) have been employed in the foam layer over many years, essentially targeting the thin liquid film on the bubbles to cause rupture and minimize any re-forming tendencies afterward. Generally, these take the form of high surface area devices that divert the foam through various small channels.

Distributors

Distributors

Calming Baffles / Anti Motion Baffles

Pipe Distributors